Custom Patches Iron On To Start Personalizing Your Clothing And Showcasing Your Identity.

Custom patches with iron-on backing have become a popular way to add a personal touch to clothing items. Whether it’s a denim jacket, a backpack, or a hat, custom patches allow individuals to express their unique style and interests. These patches can be designed in a variety of shapes, sizes, and colors, making them a versatile accessory for any outfit.

Table of Contents

One of the biggest advantages of patch iron on backing is their ease of use. Unlike traditional sew-on patches, iron-on patches can be easily attached to clothing items without the need for a needle and thread.

All that’s required is a household iron and a few minutes. This makes it possible for anyone, regardless of their sewing skills, to add a custom patch to their favorite clothing item. Additionally, iron-on patches are durable and can withstand multiple washes, making them a long-lasting addition to any wardrobe.

Understanding Iron On Backing Option

Iron-on patches offer a convenient and versatile way to add style and personality to clothing and accessories. However, not all patches come with iron-on backing, and understanding the different backing options is essential for successful application. In this guide, we’ll explore the types of patches suitable for iron-on backing options and how they can impact your customization process.

Types of Patches Suitable for Iron-On Backing

Embroidered patches are the most common type suitable for iron-on backing. Using colorful threads, they are created by stitching designs onto a base material, such as polyester or twill. These patches offer a classic and textured appearance, making them ideal for intricate designs and detailed artwork.

Application: Embroidered patches come with a heat-activated adhesive backing, allowing them to be easily ironed onto fabric. They adhere well to various fabrics, including denim, cotton, and canvas.

Woven patches are another type that can have iron-on backing. These patches are made by weaving threads together to create the design. Unlike embroidered patches, woven patches offer a smoother finish, making them perfect for designs with small text or intricate patterns.

Application: Woven patches are designed with a heat-activated adhesive backing, making them suitable for iron-on applications. They adhere well to fabrics like denim, cotton, and polyester.

3. Printed Patches

Printed patches are created by digitally printing designs onto a base material. This printing process allows for vibrant colors and intricate details, making printed patches popular for designs with gradients or photographic elements.

Application: Similar to embroidered and woven patches, printed patches come with a heat-activated adhesive backing for iron-on application. They work well on various fabrics, including cotton, polyester, and blends.

Types of Patches Non Suitable for Iron-On Backing

1. PVC Patches

PVC patches are made from a durable, rubber-like material known as polyvinyl chloride (PVC). These patches are highly resistant to water, chemicals, and extreme temperatures, making them ideal for outdoor use or in harsh environments.

Why They’re Not Suitable for Iron-On Backing: PVC patches cannot withstand the heat required for iron-on application. The high temperatures necessary to activate the adhesive backing can cause PVC patches to warp, melt, or lose their shape.

Alternative Attachment Method: Sewing is the recommended method for attaching PVC patches to the fabric. Sewing provides a secure and long-lasting bond without the risk of damage from heat.

Leather patches are crafted from genuine or synthetic leather and offer a classic and sophisticated look. They are often used on denim jackets, jeans, or bags to add a rugged and stylish touch.

Why They’re Not Suitable for Iron-On Backing: Leather is a heat-sensitive material that can be damaged by high temperatures. Ironing leather patches onto fabric can cause them to warp, discolor, or even burn.

Alternative Attachment Method: Sewing is the most suitable method for attaching leather patches to fabric. Use a sewing machine or hand-stitching to securely attach the patches without risking damage.

Chenille patches are made from a tufted, velvety material known as chenille. These patches are commonly used for letterman jackets, varsity sweaters, and other sportswear.

Why They’re Not Suitable for Iron-On Backing: Chenille patches are typically thick and plush, making them unsuitable for iron-on application.

The heat required to activate the adhesive backing can damage the delicate chenille fibers, causing them to melt, flatten, or lose their texture.

Alternative Attachment Method for Chenille Patches: Sewing is the recommended method for attaching chenille patches to the fabric. Use a needle and thread to stitch around the edges of the patch, ensuring a secure attachment without damaging the fibers.

Materials Used for Iron-On Patches

Iron-on patches can be made from a variety of materials, including cotton, polyester, and nylon. Cotton is a popular choice because it is soft and breathable, making it comfortable to wear. Polyester and nylon are more durable and can withstand more wear and tear.

When choosing a material for your iron-on patch, it is important to consider the type of fabric you will be applying it to. Some fabrics, such as silk and leather, may not be suitable for iron-on patches. It is also important to choose a material that will hold up well over time and maintain its color and shape after multiple washings.

Overall, the iron-on patch is a versatile and fun way to add personality to your wardrobe. By choosing the right type of patch and material, you can create a look that is uniquely your own.

Application Process

Preparation Steps

Before applying custom patches iron on, it is important to prepare the fabric surface properly. The following steps should be taken to ensure the best results:

- Clean the surface of the fabric where the patch will be applied. Use a mild detergent and warm water to remove any dirt, dust, or oils. Rinse thoroughly and allow to dry completely.

- If the fabric is wrinkled, iron it to remove any creases. This will ensure a smooth surface for the patch to adhere to.

- Place the fabric on a hard, flat surface. A table or ironing board works well.

Ironing Techniques

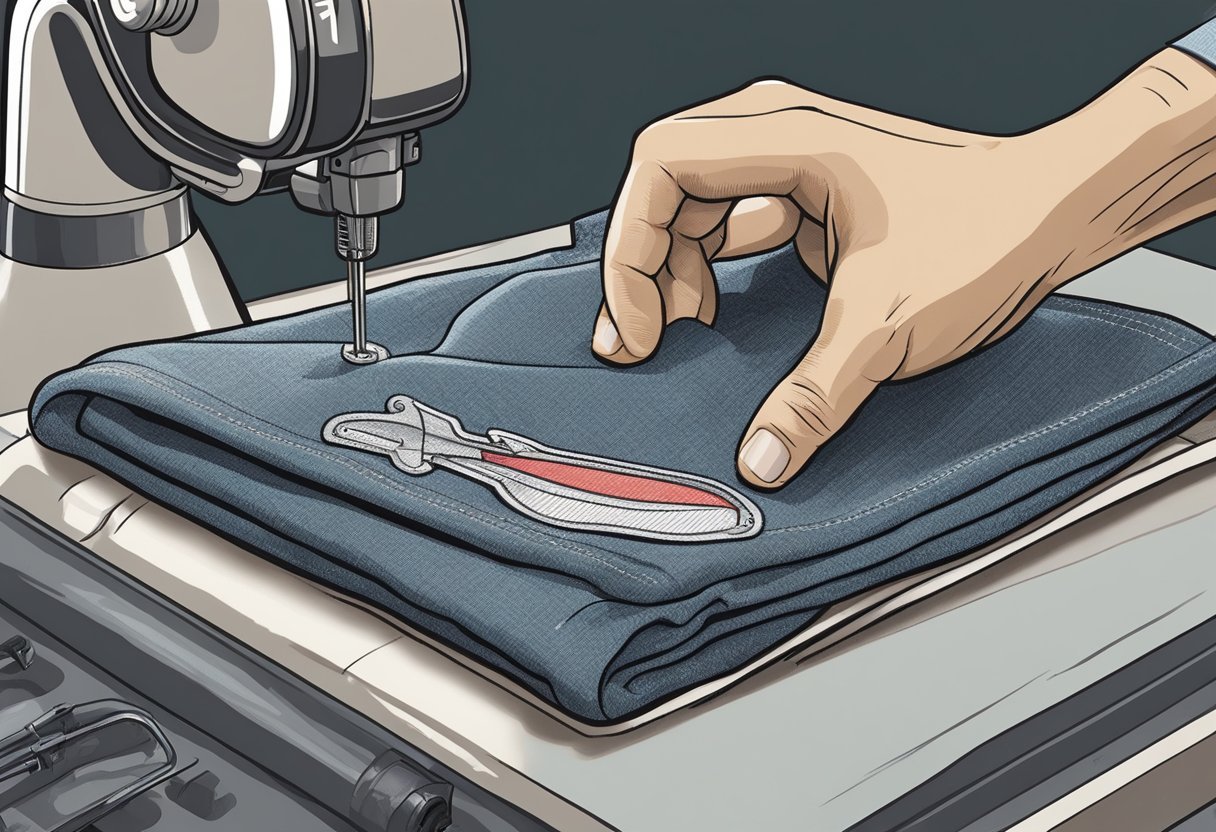

Ironing on custom patches requires a little bit of skill and patience. Follow these steps to ensure a successful application:

- Set the iron to the appropriate temperature for the fabric. Check the care label on the garment to determine the correct setting.

- Place the patch in the desired location on the fabric. Cover it with a thin, damp cloth.

- Press the iron firmly on the patch and hold it in place for 10-15 seconds. Apply pressure evenly across the patch.

- Remove the iron and cloth and check if the patch is securely attached. If not, repeat steps 3 and 4 until the patch is firmly attached.

- Allow the fabric to cool completely before wearing or washing. This will ensure that the patch adheres properly.

By following these preparation and ironing techniques, custom patches iron on can be applied easily and securely.

Care and Maintenance

Washing Guidelines

Custom patches with iron-on backing are a great way to add personality to your clothing, but they require proper care to maintain their appearance. When washing garments with iron-on patches, it is important to follow these guidelines to prevent damage to the patch or the garment:

- Turn the garment inside out before washing to protect the patch from rubbing against other items in the wash.

- Wash the garment in cold water on a gentle cycle to avoid excessive agitation.

- Avoid using bleach or fabric softeners, as they can cause discoloration or damage to the patch.

- Hang the garment to dry or use a low-heat setting on the dryer to prevent the patch from melting or peeling off.

Following these washing guidelines will help to preserve the appearance and longevity of your iron-on patches.

Long-Term Care Tips

In addition to proper washing, there are some long-term care tips to keep in mind when using custom patches iron on:

- Avoid exposing the patch to excessive heat, as this can cause the adhesive to melt and the patch to peel off.

- Store garments with iron-on patches in a cool, dry place to prevent the adhesive from breaking down.

- If the patch does start to peel off, use a hot iron to re-apply it. Place a cloth over the patch and iron for 10-15 seconds, or until the patch is securely attached.

By following these long-term care tips, you can ensure that your iron-on patches stay looking great for years to come.

Troubleshooting Common Issues

Adhesion Problems

One of the most common issues with custom patches iron on is adhesion. If the patch does not stick properly, it can fall off or become misaligned. There are several reasons why adhesion problems can occur.

Firstly, the surface of the fabric may not be clean or dry. Make sure to clean the area where the patch will be applied with a damp cloth and let it dry completely before applying the patch.

Secondly, the iron may not be hot enough. Check the temperature setting on your iron and make sure it is set to the correct temperature for the type of fabric you are using.

Thirdly, the patch may not be getting enough pressure from the iron. Press down firmly on the patch with the iron and hold it in place for the recommended amount of time.

Lastly, if the patch is still not sticking, try using fabric glue or double-sided tape to secure it in place.

Patch Durability Concerns

Another common issue with custom patches iron on is durability. If the patch starts to peel or fade after a short period, it can be frustrating. There are a few things you can do to ensure your patch lasts as long as possible.

Firstly, make sure to follow the care instructions for the fabric and patch. Avoid washing the item too frequently or using harsh detergents or bleach.

Secondly, avoid exposing the patch to excessive heat or sunlight. This can cause the colors to fade and the adhesive to weaken.

Lastly, consider using a clear coat or sealant to protect the patch from wear and tear. This can help to extend the life of the patch and keep it looking new for longer.